PRODUCTS & EQUIPMENT | TILT-UP

Mixing Products

ADMIXTURES

2023 Product Show

Power Tools

Cold Weather Items

BONDING & PATCHING

Curb & Gutter, Flatwork Forms, Stakes, & Screeds

Curing, Sealing & Protection

DECORATIVE & ARCHITECTURAL CONCRETE

EQUIPMENT

Forming

HAND TOOLS & ACCESSORIES

Inserts & Anchors

JOINTS & CRACKS

MASONRY COATINGS

MISCELLANEOUS

Rebar Fabrication

Safety Protection

TESTING

TILT-UP

UDOT APPROVED

Vapor Barrier

Tilt-up is rapidly becoming the building of choice for retail stores, schools, churches, office buildings, apartments, high-end commercial structures and even residential homes. No one knows more about tilt-up than the sales staff at Intermountain Concrete Specialties. We offer the industry’s most complete product line and engineering support services.

Hardware

We offer the world’s largest source of forming hardware and tilt-up accessories. Lifting inserts, braces, brace anchors, aluminum strong backs, rear supports, dobie, bolsters and spacers, ground release and gyro tilt systems. These are just a few of the many products available to ensure safe, efficient lifting and placement of panels. No job is too large or too small.

Accessories

No one knows concrete forming and tilt-up construction better. With dozens of brands, tens of thousands of products and a continuous history of construction innovation, productivity and product savings are built in.

Bondbreaker

We stand behind our superior product line of construction chemicals, form releases, and bondbreakers. Our brand name products are what you have trusted for years.

Visit our manufacturer websites for more details:

Dayton Superior

Plasti-Flex™ Double Chamfer Generic

Plasti-Flex™ Double Chamfer is commonly used for tilt-up concrete forms. Ultra-smooth Double Chamfer faces provide a superb architectural finish with Chamfer on both edges designed to conform thicknesses of lumber, LSL, or LVL. Plasti-Flex™ Double Chamfer is highly durable for optional reuses and great results.

FEATURE:

Efficient – quick and easy installation* onto common thicknesses of lumber, LSL, or LVL for perimeter forms and some door and window block-outs

Reusable – Highly durable plastic provides extended use

Attractive – Smooth flawless finish in concrete

Visit our manufacturer websites for more details:

Sylvan Products

Poly-Comp™ Gold Plastic Chamfer

Our plastic Poly-Comp™ Gold plastic chamfer strips deliver clean edges and straight lines in less time, with less hassle and at a low overall cost. Your customers will appreciate the smooth, flawless releases on beveled corners, panel joints or details in precast, tilt-up, and cast-in-place projects. Easy to apply with approved spray adhesives and silicon along edges on precast or tilt-up beds, and with staple guns, spray adhesives, and/or finish nails for cast-in-place job-built applications.

FEATURE:

Smooth, flawless and non-absorbent surface nearly eliminates swelling for a quick, clean release

Huge savings on finish work—little or no grinding, sacking or patching required

Easy to cut with chamfer cutters or standard wood-working tools

Little waste—available in convenient lengths, with no rough grain or knots

Clean release with little or no release agent—no sugaring or unsightly spalling

Light weight makes it easy to carry on the job—half the weight of wood or fiberboard

Flat bundles stack and store easily

Bundles well labeled on ends—easy to count and track inventory

Visit our manufacturer websites for more details:

Sylvan Products

Poly-Comp™ Gold Plastic Reveal Strip

Poly-Comp™ Plastic Reveal Strips (also known as rustication or drip strips) provided architecturally pleasing details for precast, tilt-up and cast-in-place concrete casts. The clean release provides a superior, consistent, ultra-smooth finish.

Common uses include:

- Creating featured details around panel joints and block-out areas as individual feature patterns.

- As a drip strip on horizontal surfaces to keep water from flowing toward the main building structure.

- In architectural applications to accent form liners, or often as replacement of form liners at a fraction of the cost.

Application is easy. For tilt-up and precast construction, Poly-Comp Reveal Strips can be applied to the casting bed with plastic-approved adhesives, double-sided tape, nylon nail-ins or silicon caulking. For cast-in-place construction, Poly-Comp can be applied to wood forms with staples, finish nails or silicone caulking, and with onto steel forms using plastic-approved spray glues or doubled-sided tape.

FEATURE:

Easy, clean release

Ultra-smooth finish

No sugaring, rough grain or knots like with wood reveal strips

Little or no grinding, patching or sacking required

Economical—saves material costs, and saves on labor for installation and stripping

Preferred lengths mean less waste

Well-marked bundles for efficient inventory tracking

Visit our manufacturer websites for more details:

Sylvan Products

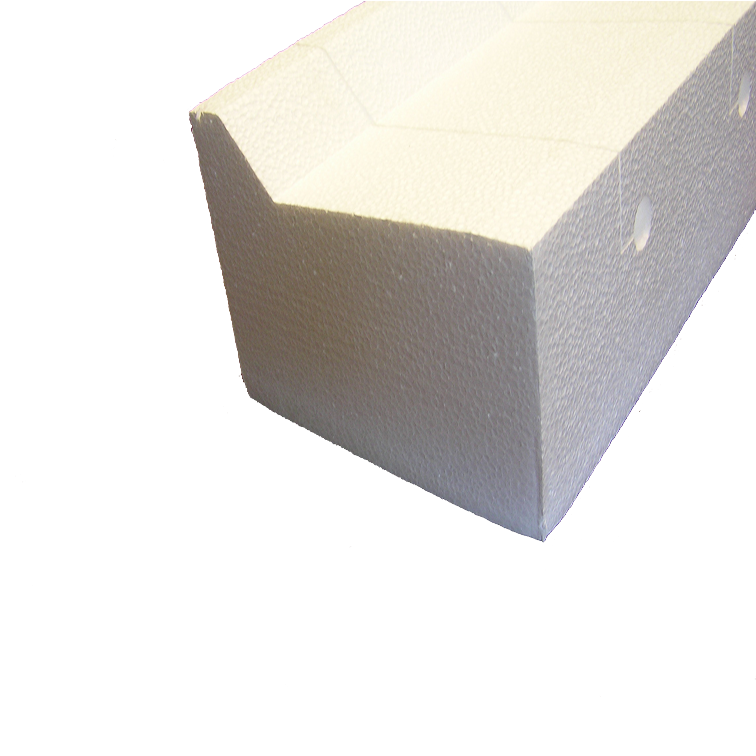

Sika Laser Form®

Concrete Slab Edge Forming System

- A better concrete slab end product

- A harder, more durable slab edge

- Consistent F-numbers from the floor center to the floor edge

- Designed to work with wide placement technologies

- No hand floating or edging

- No hand troweling

- Provides temporary edge protection

- Compatible with larger aggregates

- More efficient use of job site resources

- Rigid foam is lightweight, easy to move and install

- No special training required

Visit our manufacturer websites for more details:

Sika Laser Form